Origen re-imagined the kiln, the heart of lime production, to capture and permanently store all CO2 released during lime manufacturing. This proven, industrial-scale approach transforms a carbon-intensive material into a scalable climate solution, unlocking a stack of carbon reduction and removal pathways.

Why Lime?

A foundational industrial material

Lime is essential to producing cement and steel, purifying drinking water, refining sugar, enabling lithium extraction, treating waste, and supporting dozens of other critical industrial processes.

Inherently emissions-intensive

Producing lime requires heating limestone until it breaks down into lime and CO₂, releasing carbon as an unavoidable part of the chemistry and making decarbonization particularly challenging.

Abundant, affordable, and carbon-hungry

Limestone is quarried at billion-tonne scale through established global supply chains. When converted to lime, its highly alkaline chemistry gives it a strong natural affinity for CO₂, making it one of the most accessible carbon-binding materials available.

Origen's Unique Approach

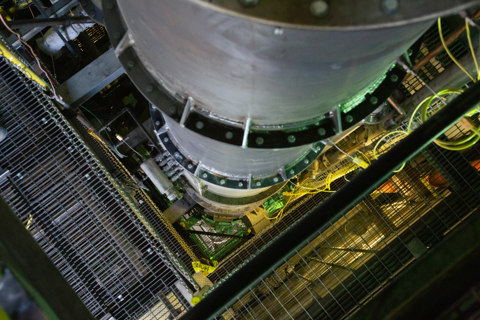

Origen’s proprietary zero-emission lime kiln is not a retrofit. It is a ground-up redesign of the lime-making process, engineered to capture CO₂ released from both the limestone chemistry and the energy used to heat the kiln. Origen’s technology produces zero-emission lime and a single high-purity CO₂ stream ready for sequestration.

By integrating CO₂ capture directly into the kiln, rather than bolting it on afterward, Origen controls emissions across the entire process without compromising industrial performance, scalability, or economics. Its fuel-flexible design avoids dependence on constrained renewable electricity, enabling reliable deployment across geographies and supporting a broad range of decarbonization and carbon removal pathways.

Learn more about the commissioning of our demonstration-scale kiln.

Designed for Real-World Commercial Deployment

Carbon Reduction and Removal Pathways Enabled by Lime

Once lime can be produced without emissions, its role in the climate transition changes fundamentally. Zero-emission lime eliminates the carbon footprint of an essential industrial material, reducing the carbon intensity of everything lime touches. Beyond that, it becomes a versatile decarbonization platform, enabling emissions reductions across other hard-to-abate sectors and unlocking some of the most scalable carbon removal pathways available.