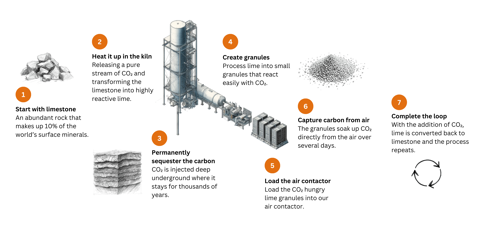

Our technology was designed to operate with today’s resources and fundamental chemistry to secure our future. We combine the natural properties of limestone with proven industrial technology to permanently remove CO2 from the atmosphere.

Carbon removal at gigatonne scale is no longer optional

10 billion tonnes

All credible climate pathways show the same requirement: in addition to cutting emissions, the world must remove ten billion tonnes (gigatonnes) of CO₂ from the atmosphere per year by mid-century to limit global warming to 1.5°C. This means building a new industry operating at a scale matched by only a handful of global sectors today.

$1 trillion market

With governments beginning to regulate emissions and companies committing to net-zero targets, demand for durable carbon removal is accelerating rapidly. By 2030, the carbon dioxide removal (CDR) market is projected to reach $10 billion annually, and by 2050 it is expected to exceed $1 trillion. This means carbon removal will be the world’s largest new infrastructure market.

Why Direct Air Capture is Essential

Direct air capture (DAC) is one of the most promising approaches for removing CO₂ from the atmosphere, offering verifiable, permanent sequestration. Unlike many other carbon removal pathways, it is not constrained by land or biological inputs, giving it the potential to scale to the multi-million-tonne levels required for meaningful climate impact.

However, many DAC technologies today remain costly, electricity-intensive, and unproven at scale. Scaling DAC requires more than chemistry — it demands industrial design choices that reduce cost, complexity, and deployment risk.

The world needs direct air capture that can deliver.

We designed a practical approach to de-risk the path to industrial scale.

Fully Integrated System

Limestone-based DAC requires two core elements: a kiln and a contractor. We own both, enabling tight system integration and a clear path down the cost curve.

Low Intensity Contactor

Optimized lime production and handling enable a low-intensity air contactor design, minimizing energy use and reducing system complexity.

Scalable,

Affordable Inputs

A fuel-flexible kiln avoids reliance on constrained renewable electricity, while limestone feedstock is abundant and globally available, enabling a system built for scale.

Permanent Carbon Storage

Geological sequestration deep underground is scientifically proven to lock away CO2 for over 1,000 years.

Origen's Direct Air Capture System

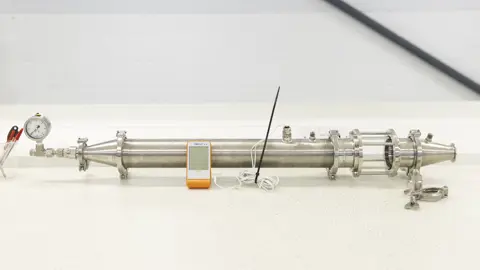

Zero-emission lime kiln – we use a proprietary design to drive CO2 out of limestone. Fuel flexible (e.g. ability to be low electricity-demand) with TRL 9 components.

Low-intensity contactor – we let nature do its work with simple mechanical structures that facilitate natural chemistry of the calcium-carbon loop for low-intensity CO2 capture

High performance lime – we engineered calcium oxide, also known as lime, specifically for DAC and use Origen's breakthrough proprietary processing to maximize its ability to remove CO2 from the air